According to my experience, failures of electronic devices have three main causes, 1, highly complex systems with inherent reliability issues because of all too many parts – these systems can only function with regular maintenance and repair, 2, high power circuits that run hot or otherwise stressful conditions, eventually, parts will fail, 3, bad design or insufficient design margin to reach lifetime expectations; even the best-designed system will eventually fail unless it is a very low power dissipation system of very low complexity (say, a telephone relais or a light switch).

Surely, for machine tools the life time expectations have been subject to change over the decade. 100 years back, a good metal working machine was made to last 100+ years, a major capital investment, and the complexity of such machines was kept low, heavy castings, and the machining done with conventional tools that had very little productivity overall – surely no comparison to the human-operated hand tools when it comes to machining metal, but also no comparison to nowadays high performance machinery. With the Saacke – a machine of quite some complexity with certainly over 1000 components, consisting of an estimated 30000+ single parts in total, 1000+ meters of wires, etc., the motors and controls have certainly held up to expectation after nearly 40 years, but the eventual failure of the NI 3426 can likely be traced to a combination of factors 2 and 3, say, the motor switching contactor selecting the Y-Z drive in combination with DC currents of 5 Amps, high inductance coils, difficult timing requirements of switching (only open or close the contactor after full decay of motor current), along with aging semiconductors and semiconductors of low design marking (e.g., C-E break-down voltage 125 V or the RCA 41013 used on the D190 current drive board, vs. 90 V operating voltage). It must have been some cost-performance evaluation at the time, along with the limitations of control systems for 4-axis control at the time, for Saacke to decide to select a single drive-two motors topology, and use one of the infeed controllers to drive either the Y or Z axis, rather than to provide drive systems and control for Y and Z individually.

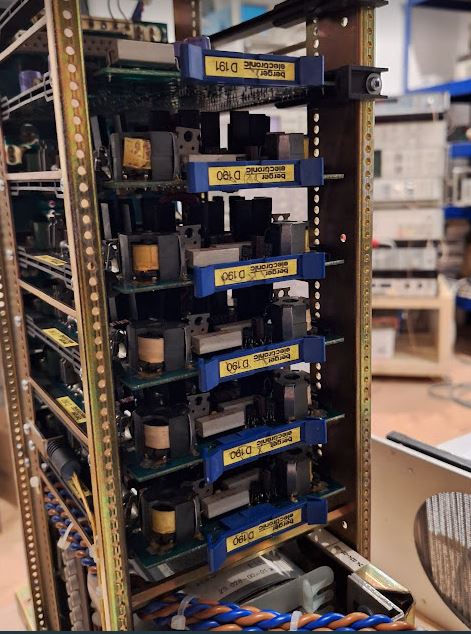

A big advantage of the industrial electronics used here is their accessibility and serviceability, basically, all that would be needed are two new D190 assemblies, and you could bring back the machine to service within less than 20 minutes downtime, if you had certain Berger Lahr spare parts in stock. Barely a few hours if you had to pick them up at some Berger Lahr warehouse if you are in the South-West corner of Germany.

Their is ample free spaces in the case used to guide air through it with a big fan, keeping everything cool. The old engineers know that there is a direct correlation between operating temperature and lifetime of semiconductors!

There are the five identical current regulator cards, D190.

The “test points” for the current at the back panel – all the supply voltages, motor connections, and digital controls are routed through that panel, easily accessible for test.

Surely, Berger Lahr has long been renamed and sold to Schneider Electric, and they even don’t respond to enquires of private individuals, nor offer any service documentation for legacy equipment, as much as I can say, is a supercilious company now that has no time to devote to service of legacy products. Anyway, we are an electronics repair shop here, and fortunately, some paper documents came with the Saacke machine, including, a schematic of the D190 board – without part numbers, but at least, identifying the location of parts on the board, and a detail functional description of the circuit.

Q12, BC237B, a typical 80s NPN small signal transistor, Q16, BC251B, a small signal PNP failed, along with the power transistors, a Texas Instruments PT1132 and a RCA 41031. Also checked the Q14 transistor, PT1131, a rather rare transistor, but it seems to be just a typical fast NPN medium power transistor, nothing too special, and, it is working!

Doing some further research, also desoldered the good power transistors from the boards, and check the current gains:

PT1132, hfe: one has 30, one has 25 (anyway, these transistors are good, no need to replace)

PT1131, hfe: one has 46, one has 21

RCA 41031: one has 33, one 109(!) current gain.

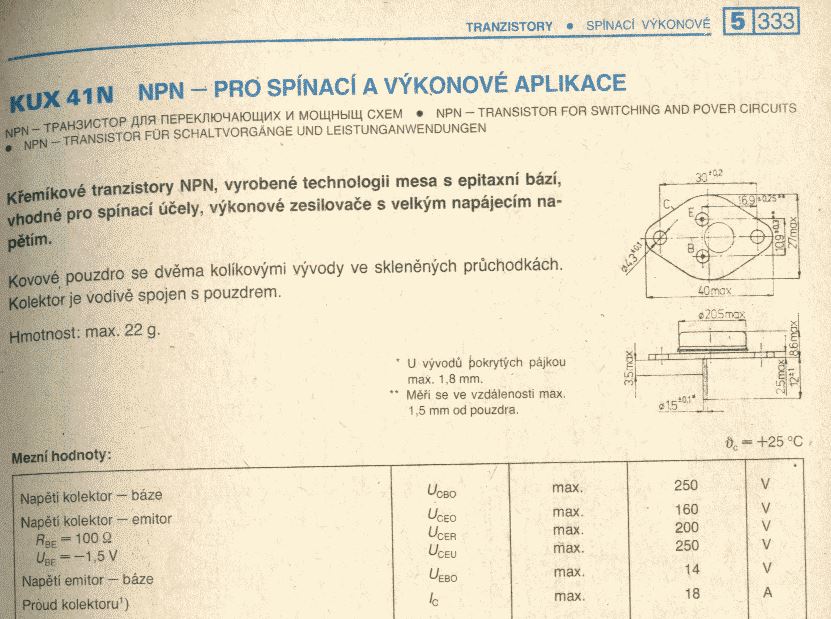

Definitely, we need to use replacement that have reasonably high current gain, say, at least 20, sufficient breakdown voltage, say, more than 150 Volts, and roughly 10 Amps current carrying capacity.

The BUX41 is indeed a good choice for these, and, because these are used even by Berger Lahr on some of their newer boards, surely valid replacements. It is not quite clear why they used a combination of the RCA 41013 and PT1132 in the first place – could be because of gain, voltage ratings, or switching time considerations.

To get some BUX41 is rather easy, but prices are in the range of 5 to 15 EUR a piece, well above what I am willing to spend on a repair attempt, given that I need 8 pieces (no intention to re-use the working power transistors, because they may eventually fail or may have suffered some damage.

A kind reader of the earlier post pointed me to the “Tesla”-made devices, KUX41N, these would really be a good choice, but I would have to buy them from outside Germany, and there is no easy way to order them from Germany.

In some past project I have used power transistors of Tesla brand, and these really held up well, heavy duty cases, strong wires. They didn’t save on copper when making these.

The cheapest I could find were some BUX41 on Aliexpress. It says real but looks fake (the vendor even removed the “ST” logo on the picture”), anyway, let’s order a few.

After short waiting time, an envelope arrived with the “BUX41” transistors, and following good habbit, I had ordered 10 pieces, 8 for the repair job, 1 spare, and, one for fake analysis. These may or may not be original BUX41 dies, but it is good practice to have a look inside these to check at least the silicon area (sometimes there are just very tiny transistors inside that won’t be able to deliver the current), the heat conduction pad (sometimes absent), and the wire bonding (sometimes lousy). In my case, the BUX41 looked quite good inside.

Solid bonding wire, a strong heat conduction bag, solid case. Only the marking comes off easily, and the cases look polished/ground with sandpaper on the top.

So these must have been some generic high-power higher-voltage higher-gain NPN transistors that were then labeled BUX41.

When doing gain tests, 6 came out as 35-45, 3 as ~25, not bad. Used the higher gain transistors for the upper section of the H bridge, having the transformer driver.

Further testing the Aliexpress BUX41, I pulled out my old Harrison Laboratories 6209A 320 Volts D.C. Power Supply. With the base floating, not conduction up to the maximum voltage, roughly 325 V over the E-C junction. Also checked the RCA 41013 (good parts), and these break down at ~140 VDC.

With some fresh heat conduction paste, all the transistors mounted and soldered to the D190.

The small signal transistors, even found an original BC251B in my collection, but no BC237B – replaced it by a BC547B.

With the transistors installed, I checked all the transistors and diodes with a diode tester, to check the voltage drop, and compared it to a good assembly. Also checked all the voltages at the electrolytic caps, with the diode tester. Good practice to check for shorts.

Next, I connected the circuit to a power supply (+12 V, -8 V are needed) – the circuit is operating fine, the H bridge switching properly. Then I dared to install it back to the Berger Lahr drive, and powered it on.

One of the largest stepper motors ever on my workbench, it starts to turn. Repair success!

Also left it switched-on and turning for some hours, temperature is low. Regulated the current to ~3 Amps, plenty enough for that motor unless you need maximum torque.